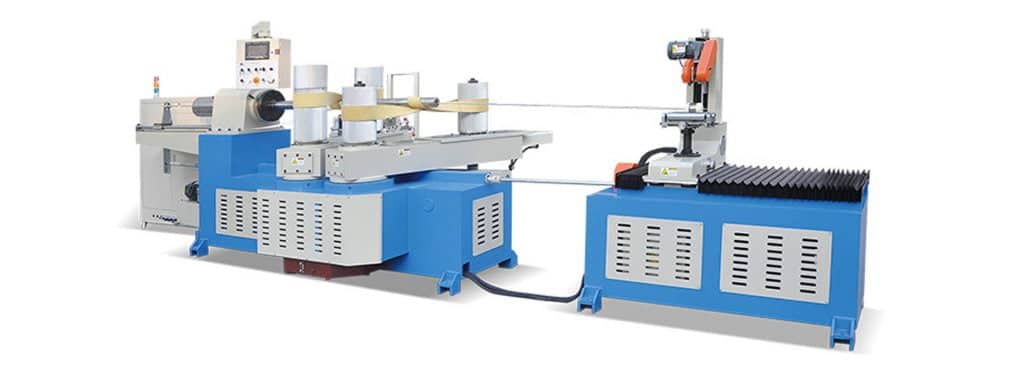

“E” series of paper tube machine, simple, compact and stable design idea. Standard for making 6” paper tubes (ID 152.4 MM), maximum wall thickness less than 15 MM, largest tube inner diameter up to 300 MM. Usage: all kinds of film winding, paper winding, all kinds of medium-sized industrial paper core. The model can produce spiral paper tube with gluing, winding and cutting.

Characteristics

| parameters | Transmission system | ||

|---|---|---|---|

| No Of Layer | 3-24 layers | Main motor power | 15kw |

| Max-Inner Diameter | 300mm | Revolving speed of winding nose | 47 R/Min |

| Min-Inner Diameter | 25mm | Output torque of winding nose | 2720 NM |

| Max-Thickness | 15mm | Way of transmission | Gear & Chain |

| Min - Thickness | 0.5mm | Model of transmission chain | 16A*2 |

| Way Of Mandrel Fixing | Flange & push | Drive of winding nose | 4 wheels |

| No of winding nose and belt | Four noses and two belts | cutting motor | Stepping motor/Wanxin Gear motor |

| Way of cutting | Single circular cutter | Bearing | HRB |

| Way of gluing | double face | Control system | |

| Way of length locating | Encoder | PLC controller | Delta |

| Operator | 1-4 People | Man-machine interface | Color touch screen weinview 6070T |

| Productivity speed | 3-20M/Minute | Program version | DELTA 15KW |

Leave us a message and we will be happy to contact you to work together on a solution. Do not hesitate to share all your concerns with us, one of our experts will assist you.